Hollow anchor: nine advantages of hollow anchor

- Categories:Industrial News

- Author:欣本

- Origin:www.lyxbjx.cn

- Time of issue:2020-11-26 11:26

- Views:

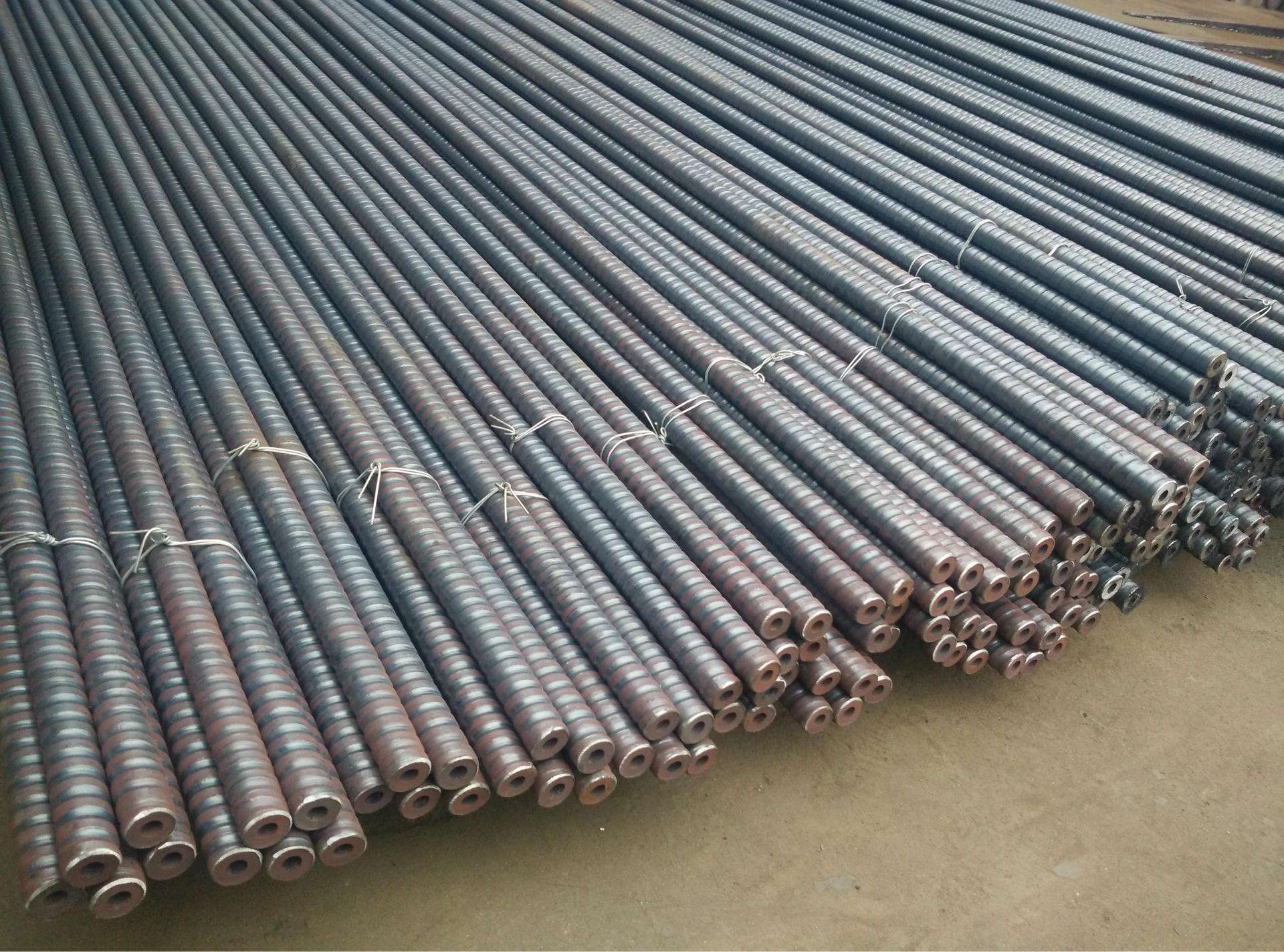

(Summary description)Hollow anchor rod The anchor cable body adopts a hollow design scheme, and the middle hole of the rod body is used as a high pressure wind and water channel and a grouting channel.

Hollow anchor: nine advantages of hollow anchor

(Summary description)Hollow anchor rod The anchor cable body adopts a hollow design scheme, and the middle hole of the rod body is used as a high pressure wind and water channel and a grouting channel.

- Categories:Industrial News

- Author:欣本

- Origin:www.lyxbjx.cn

- Time of issue:2020-11-26 11:26

- Views:

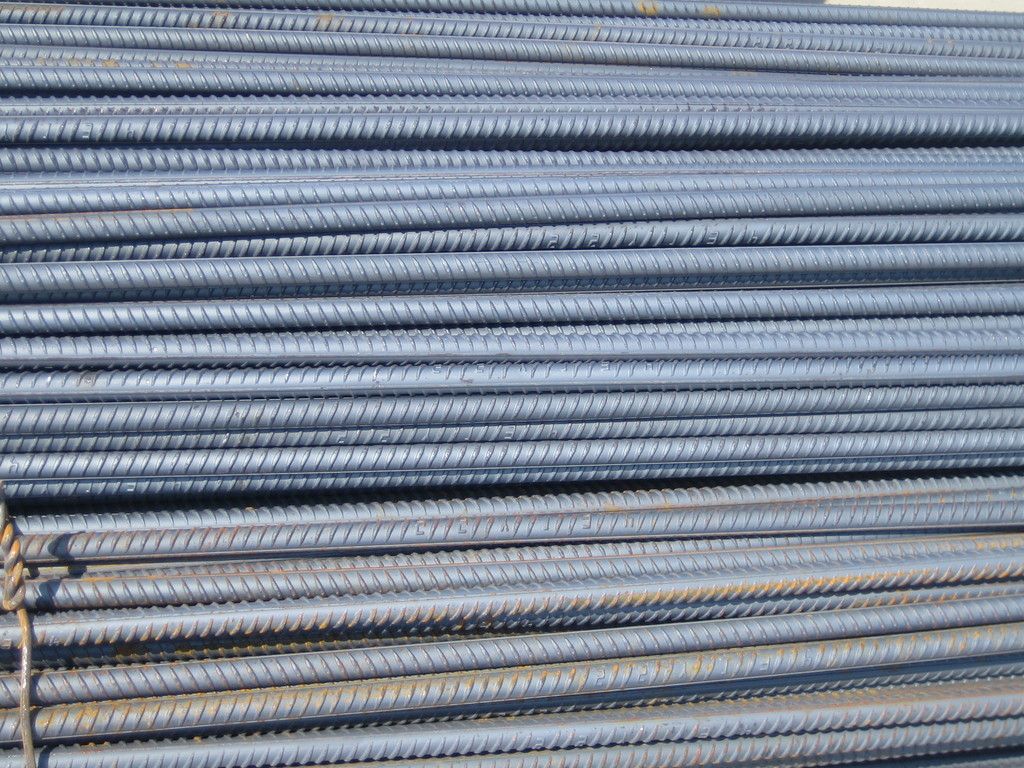

Hollow anchor rod The anchor cable body adopts a hollow design scheme, and the middle hole of the rod body is used as a high pressure wind and water channel and a grouting channel. Compared with a solid rod body, the hollow rod design scheme can obtain stronger bending rigidity and tensile strength. The total length of the outer surface of the anchor cable body is standardized with a large pitch external thread structure. The external thread structure is convenient for laser cutting and connection of the anchor cable. Compared with the smooth rod body, the total bonding area of the anchor cable body and the grouting material is increased, thereby increasing the anchoring force of the steel bar. .

Hollow grouting bolt The compressive strength of the hollow bolt body is above 300MPa; the torque exceeds 40N·m, its tensile strength is lighter, and it can be laser cut, is not easy to destroy the automatic cutting machine, and the surface is anti-static , Flame retardancy, laser cutting does not cause flames, corrosion resistance, heat insulation and insulation layer, long-lasting durability.

The nine application advantages of Xinben recommended hollow bolts:

1. Hollow bolt design is flexible, purposeful and adaptable. According to different roadheader models, geological standards and coal road cross section regulations, the design scheme can be double-arm or arm hollow grouting bolt method; hollow bolt manufacturer

2. The structure is relatively simple, and it is very easy to check and repair common faults. The hollow design scheme completes the function of grouting; the grouting is round and can complete the working pressure grouting. The centering of the rod body is good, and the cement mortar can encapsulate the total length of the anchor cable body, preventing the probability of rust, and achieving the purpose of long-term bolt support. The installation is convenient, without the need for on-site production and processing of external threads, the pads and nuts can be easily installed.

3. Incorporating into the coal roadway with a wide cross-section coverage, consider the support of most of the top and side anchor cables in different coal roadways and general technical specifications. Compared with continuous coal mining machines and digging anchors, it can be integrated into coal. The lane height-to-width ratio and total width specifications are relatively small;

4. Reduce the labor efficiency of employees and improve the anchoring office environment-in a fully mechanized coal roadway, when the roadheader cuts the coal and after the coal is discharged, the roadheader is pulled back 3-5m, and then a single bolter is moved to work. Drilling work is carried out on the work surface. After the drilling work is carried out, a single bolt drill must be removed from the work surface. This process is coordinated with the hollow anchor rod, which can prevent the employees from constantly moving a single anchor rod drill, and drilling can be carried out without manually moving the anchor rod drill, but simply control the valve handle;

5. The volume of the tunnel boring machine is relatively small after the hollow grouting bolt is modified, which can show a relatively fat working natural environment for the mine staff, which is convenient for the production and manufacture of the mine staff, and it is also convenient for natural ventilation of the excavation head;

6. The hollow grouting bolt has little harm to the characteristics of the cantilever roadheader, including the convenience of the roadheader's actual operation, the position of the center of gravity after the hollow grouting bolt is installed, the change of the specific pressure of the grounding device, and the maintenance after supporting facilities Check the degree of difficulty, etc.;

7. The supporting facilities of L-band hydraulic machine bolter drill and cantilever roadheader are selected, which simplifies the system structure. The hydraulic machine bolter and the roadheader hydraulic machine information system are integrated, and a set of hydraulic transmission system is used together, so that the extra expenses incurred by the separate power unit for the bolter rig can be saved;

8. The hollow grouting anchor rod of the roadheader requires fewer workers. Except for the process flow of dismantling and replacing drilling tools, installing anchor cables, and charging, all other actual operations are carried out by one person;

9. After the coal is cut and discharged, the roadheader can be anchored without pulling back the roadheader, thus reducing the harm caused by the roadheader's continuous backing and forwarding, and improving the natural environment of the coal roadway.

The above is the content collected by Luoyang Xinben Machinery Equipment Co., Ltd., the editor for everyone, if you need to develop it, please contact us.

Scan the QR code to read on your phone

Relevant Information

SAUNDERS

WRITE A MESSAGE TO US

Contact Us

0086-0379-6371-8859

Address:No.389, Luobai Road, Luolong District, Luoyang City, Henan Province

Manager Cheng:0086-013838885350

Manager He:0086-013938887290

Email:lyxbkj@163.com

Follow us

-

WeChat

- Hotline 13938887290

- Back to top

Webpage Copyright(c) Luoyang Xinben Machinery Equipment Co, Ltd. Powered by:300.cn 豫ICP备20006943号-2